Quality assurance

Quality assurance

Receiving Inspection of Purchased Products

At Vijaya Machine Tools, quality begins right at the source. Every purchased raw material undergoes chemical and physical testing as per the defined control plan. Materials such as bright bars, profiles, forgings, castings, and other assembly spares are checked against strict standards. In addition, dimensional inspections are carried out to ensure that only the highest-quality inputs are used in our manufacturing process.

In-Process Inspection

We implement rigorous in-process inspections to maintain precision throughout the production cycle. This includes testing raw materials, dimensional verification, and setup approval of every manufacturing process as per customer drawings and plans. To ensure consistency, hourly inspections are conducted during production, with clear identification and traceability of any non-conforming products. This guarantees efficiency and accuracy at every stage of machining.

Final Inspection

Before delivery, each product undergoes a comprehensive final inspection. This includes 100% visual checks to detect rust, blow holes, dents, rough finishing, tool marks, or any missing operations. Additionally, sampling and full dimensional inspections are performed on critical features with tight tolerances. Any non-conforming parts are segregated and documented, ensuring that only products meeting our stringent quality standards reach the customer.

Quality

Quality Assurance

Development

Engineering & Development

Focus Areas

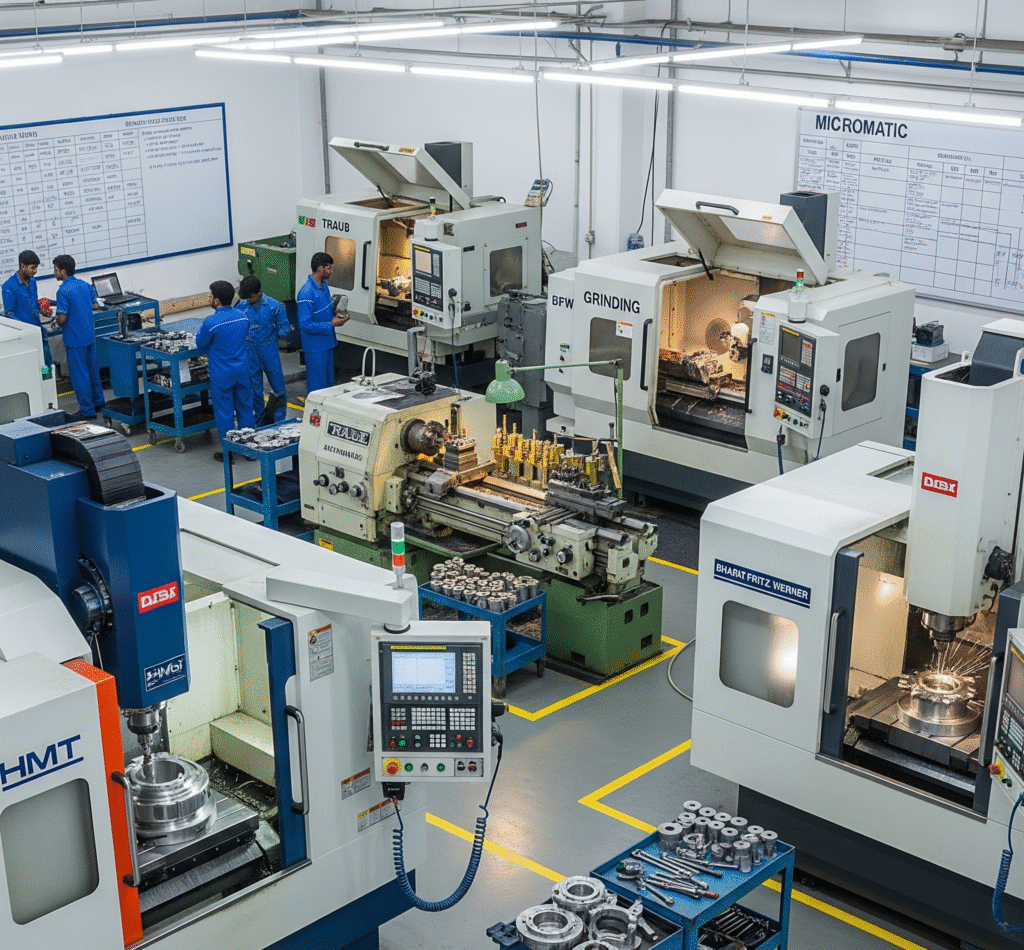

We follow strict quality control measures at every stage of production. From raw material inspection to final delivery, every component undergoes precise testing to ensure accuracy, durability, and international standards compliance.